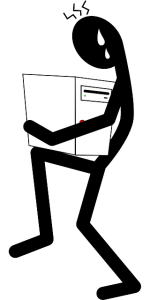

Proper lifting technique begins with proper delivery and storage. Plan incoming deliveries when enough labor is available to assist without straining. According to Liberty Mutual’s five year study, overexertion is the number one cause of on the job injuries. We can manage and do better.

Proper lifting technique begins with proper delivery and storage. Plan incoming deliveries when enough labor is available to assist without straining. According to Liberty Mutual’s five year study, overexertion is the number one cause of on the job injuries. We can manage and do better.

Check supplies in, and then put them where they belong. By storing materials quickly, hallways, loading docks, and work areas stay uncrowded. And, employees know where to store and find supplies.

Muscle pulls can occur with relatively light weights. To reduce the frequency of these pulls, try to organize storage so a minimum of reaching high or bending low is required, especially with heavier objects.

Store twenty pound objects at waist height. Any object weighing more than twenty pounds should be stored where hand trucks can be used to move the objects. Do not store objects higher than five feet. People should not reach over their heads to retrieve an object. Reaching risks dropping a load on the employees head.

Sounds like you need more storage space? First, try disposing of all that top shelf long-term stuff. Everyone in business has a certain amount of clutter that accumulates over the years. It’s similar to the attack or garage. Space tends to fill up with stuff. Clean it out. Psychologically, it will make you feel leaner as a company.

Do not overcrowd storage areas. Overcrowding promotes two bad hazards. Trips and falls occur more frequently in overstuffed storage areas. Unusual twisting and bending of the torso occurs more frequently in disorganized or overcrowded storage.

Design and designate storage space so adequate supplies or materials can be on hand without employees needing to twist, turn, strain or trip and fall to get them. Organized, safe storage promotes more professionalism. People tend to maintain inventory as they find it. Safety is the result of proper planning and implementation of storage management.